Screw jacks

Informations

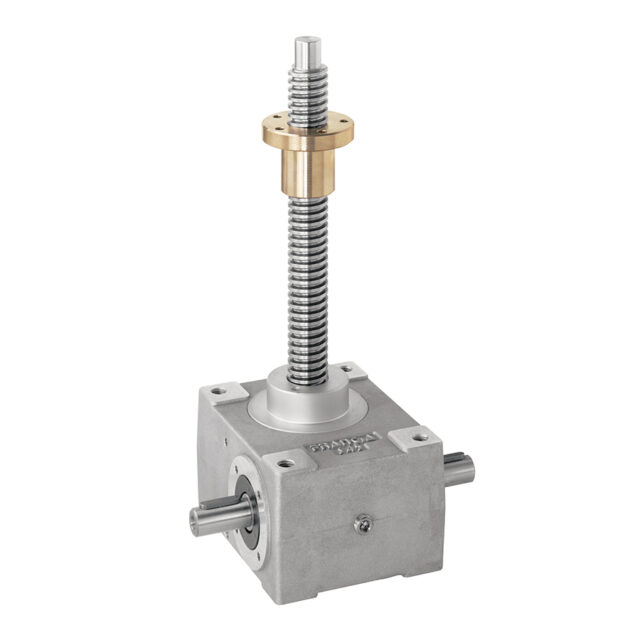

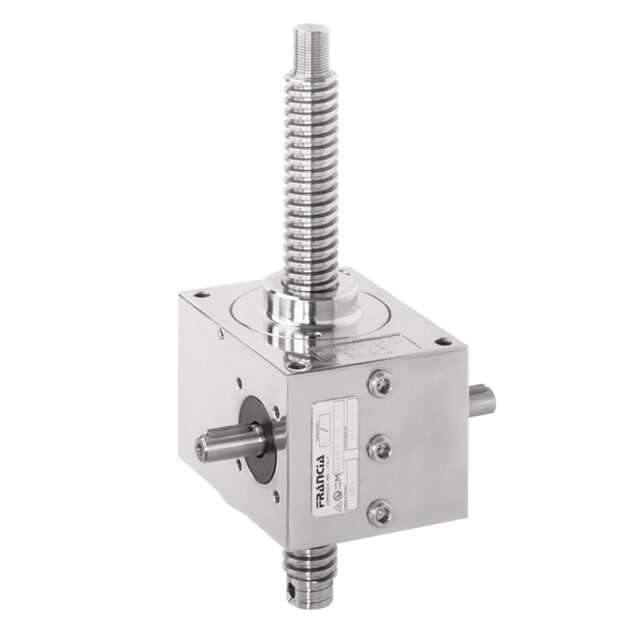

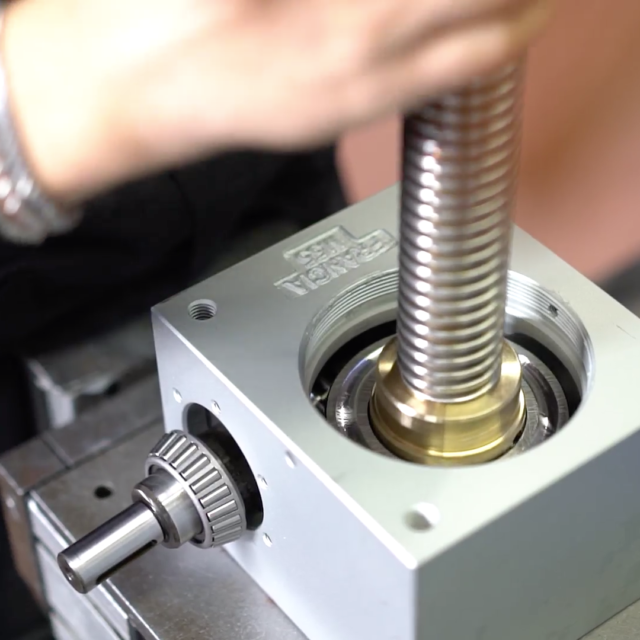

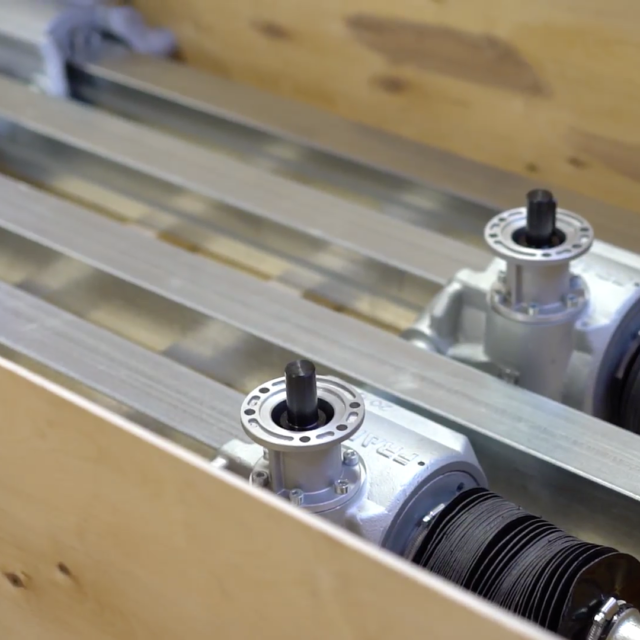

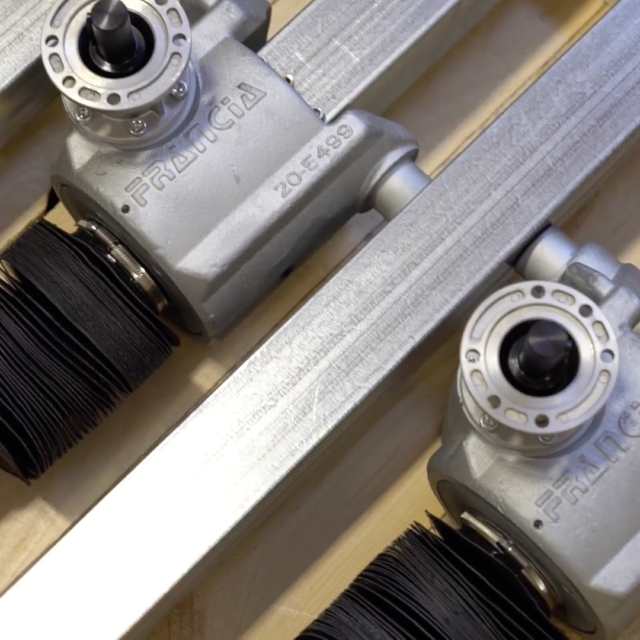

We manufacture trapezoidal screw jacks up to 400 kN (lead screw Tr100x12) with ball lead screws on request too, Execution type translating screw (VT) and rotating screw (VR).

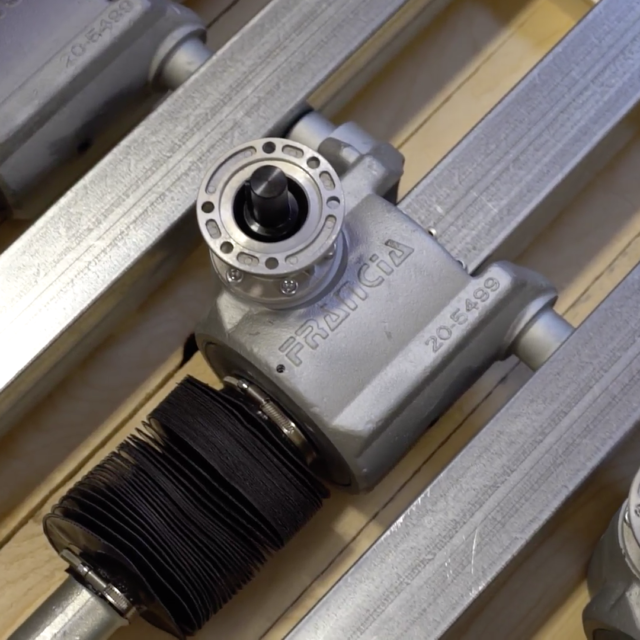

We can provide a wide range of accessories like protection tube (TQ), bellows (CS), motor flanges (PMG), etc …

Preliminary warnings

FRANCIA screw jacks undergo inspection and quality tests during assembly and before packing. When starting up the machine or system on which screw jacks are installed, it is necessary to lubricate the lifting screw and remove, if present, foreign bodies and impurities of various kinds (poor, shavings). The electrical end-of-stroke devices (if present) of the system to be handled must be carefully checked to avoid the mechanical end-of-stroke of the jack itself. It is advisable, where possible, to start the machine or system with the load and proceed to the test in steps under normal operating conditions and the desired load.

Technical details

Description

The mechanical screw jack is a device which transforms an input rotating movement in an output linear movement. It can be used singularly or in multiple combination by shafting, coupling and bevel gear units. It can be manually or motor powered, by electric motor DC or AC and also by hydraulic motor.

Use

They are used to align, to move, and to set of every kind of load.

Advantages

- Easy application, high reliability and minimum servicing;

- Safety and high precision positioning thanks to the inner mechanical system;

- Irreversibility: they are able to maintain the load applied even if a stop incurred without any use of brakes or other kind of block systems.

- Synchronised movement even with unevenly distributed loads. Evenly distributed loads.

Mounting operations

During the mounting operations it is necessary to avoid to apply radial load on the lifting screw and on the input worm shafts.

It is necessary to check:

- to respect the squareness between the lifting screw and mounting base of the jack;

- to respect the squareness between the lifting screw and mounting base of the lifting screw/nut;

- The load direction is axial respect the lifting screw (see lateral loads FL).

Servicing

The mechanical screw jack must be checked frequently also according to the work environment, the working time, speed of lifting screw and cycles of work per hours. In every mechanical screw jack with trapezoidal screw it is absolutely useful pay attention to the wearing of the nut or the wheel.